INTRODUCTION

A Detroit-based ground beef producer operating across three locations wanted to enhance its production efficiency, product quality, and operational safety in 2018, so it chose Rome Grinding Solutions as its trusted partner. The collaboration focused on replacing an existing bone elimination system with the advanced Rome Reclaim System (RRS), a solution that provided significant improvements in yield rates, product quality, and sanitation.

Challenges and Goals

This customer faced several challenges in its production process, including an inefficient bone collection system, operational downtime, and sanitation concerns. The company’s existing bone elimination system was unable to maximize product recovery, leading to increased waste and lower yields. The competitor’s system also had complex setup procedures, contributing to longer downtime and reduced production efficiency. Finally, the complexity of maintaining the system led to sanitation challenges, increasing the risk of contamination and extended cleaning times.

The company wanted a solution that addressed these inefficiencies while improving overall yield and product quality. They also aimed to streamline setup, reduce downtime, and enhance sanitation protocols in their plants.

“With the RRS system, our customer saw a substantial improvement in efficiency. The system’s ability to recover nearly all of the product led to significantly reduced waste. The system also allowed operators to work faster, cutting down on setup and maintenance time.”

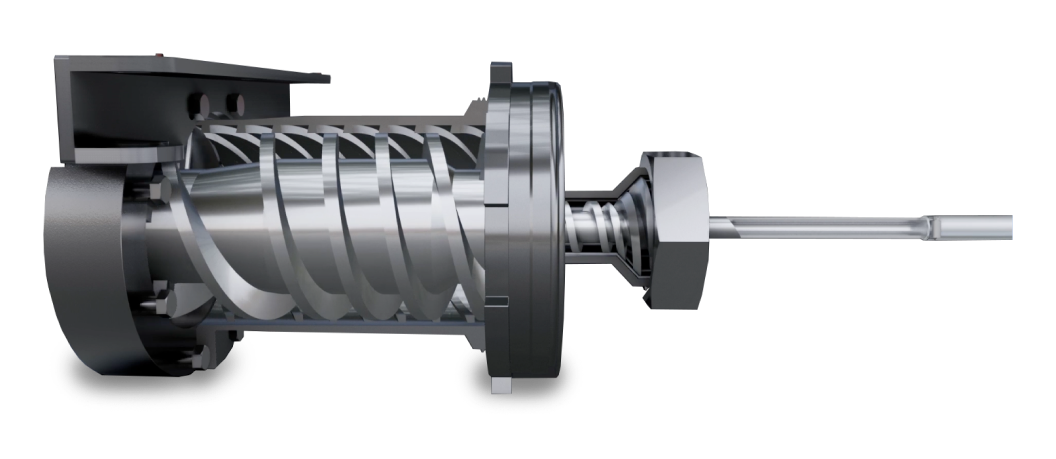

The Solution: Rome’s RRS System

The Solution: Rome’s RRS System Rome Grinding Solutions introduced the RRS as a replacement for the existing system. The RRS system offered five distinct advantages over the competition:

Higher Yield Rates:

The RRS system captures up to 99% of the product, significantly increasing yield rates. Unlike traditional bone collection systems, which often produce more waste, the RRS system is designed to recover more valuable white meat and reduce red meat waste.

Cost-Effectiveness:

The RRS system ranges in cost from $18,000 to $28,000, depending on size, providing a more budget-friendly alternative compared to other systems

Improved Sanitation and Maintenance:

With fewer moving parts, such as motors and gearboxes, the RRS system reduces the risk of contamination. Its design allows for easier cleaning, addressing the sanitation concerns previously faced.

Streamlined Setup:

The RRS system is quicker and easier to set up, reducing operational downtime and increasing production throughput.

Temperature Control for Product Quality:

Maintaining consistent temperatures between primary and secondary plates is crucial for product quality and shelf life. The RRS system ensures better temperature control, thus improving product consistency.

Implementation and Results

After successful trials of the RRS system in 2018, the customer began transitioning its production plants to the new system, starting with their North Plant and later installing two additional grinders at its Forest Park Plant. As a result, the company experienced increased efficiency, positive feedback from staff, a rapid return on its investment, and sanitation improvements.

The RRS system produced a substantial improvement in efficiency. The system’s ability to recover nearly all of the product led to significantly reduced waste. The system also allowed operators to work faster, cutting down on setup and maintenance time.

Production supervisors and operators appreciated the ease of use and the quality of the final product. The team reported that the system’s intuitive design and simpler setup resulted in less downtime and a more efficient production process.

The RRS’s ability to capture more valuable product helped the customer realize a rapid return on investment. In facilities processing large volumes of ground beef, the ROI is often seen within just a few weeks of implementation.

The simplified design of the RRS system made it easier to clean and maintain. The company’s production team reported that the new system significantly reduced the time and effort needed for sanitation, leading to less production downtime and lower contamination risks.

Future Expansion and Continued Partnership

Based on the success of the RRS trial and installation, this customer expanded its use of Rome’s equipment across more of its production facilities. The improved yields, reduced waste, and better operational efficiency have positioned the company for future growth. Rome Grinding Solutions continues to work closely with similar customers, offering ongoing support, and exploring additional ways to optimize their production lines.

Key Takeaways

This collaboration demonstrates the transformative impact that innovative equipment can have on meat processing operations. Rome’s RRS system not only improved yield rates but also enhanced operational efficiency, sanitation, and product quality, making it an ideal solution for producers seeking to optimize their ground beef production.

Connect With a Rome Expert

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557