INTRODUCCIÓN

Un productor de carne molida de Detroit que opera en tres ubicaciones quería mejorar su eficiencia de producción, la calidad del producto y la seguridad operativa en 2018, por lo que eligió a Rome Grinding Solutions como su socio de confianza. La colaboración se centró en reemplazar un sistema de eliminación de huesos existente con el avanzado Rome Reclaim System (RRS), una solución que proporcionó mejoras significativas en las tasas de rendimiento, la calidad del producto y la higiene.

Desafíos y Objetivos

Este cliente se enfrentó a varios desafíos en su proceso de producción, entre ellos, un sistema de recolección de huesos ineficiente, tiempos de inactividad operacional y problemas de saneamiento. El sistema de eliminación de huesos existente de la empresa no podía maximizar la recuperación del producto, lo que generaba un mayor desperdicio y una menor producción. El sistema de la competencia también tenía procedimientos de configuración complejos, lo que contribuía a un mayor tiempo de inactividad y una menor eficiencia de producción. Por último, la complejidad del mantenimiento del sistema generaba problemas de saneamiento, lo que aumentaba el riesgo de contaminación y prolongaba los tiempos de limpieza.

La empresa quería una solución que abordara estas ineficiencias y, al mismo tiempo, mejorara el rendimiento general y la calidad del producto. También buscaba optimizar la configuración, reducir el tiempo de inactividad y mejorar los protocolos de saneamiento en sus plantas.

“Con el sistema RRS, nuestro cliente vio una mejora sustancial en la eficiencia. La capacidad del sistema para recuperar casi todo el producto permitió reducir significativamente los desechos. El sistema también permitió a los operadores trabajar más rápido, lo que redujo el tiempo de configuración y mantenimiento”.

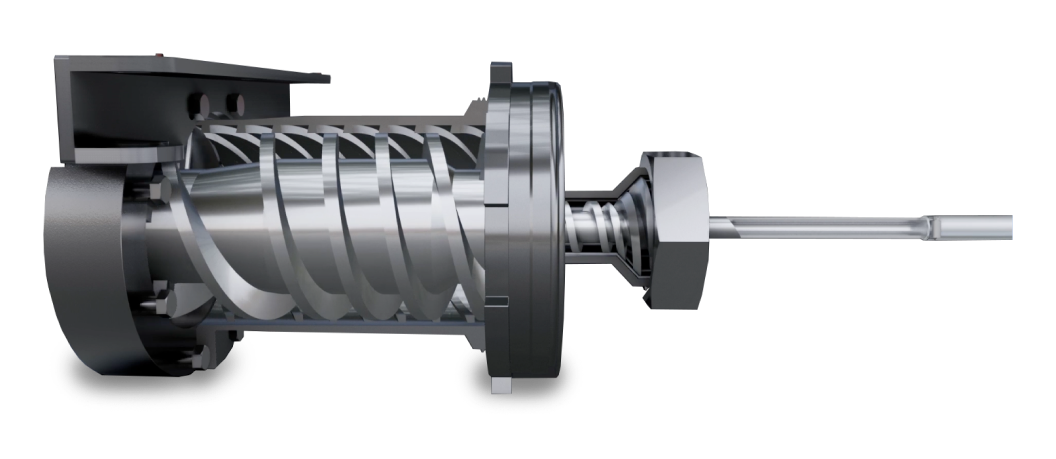

La Solución: El Sistema RRS de Rome

La solución: el sistema RRS de Rome Rome Grinding Solutions introdujo el sistema RRS como reemplazo del sistema existente. El sistema RRS ofrecía cinco ventajas diferenciadoras con respecto a la competencia:

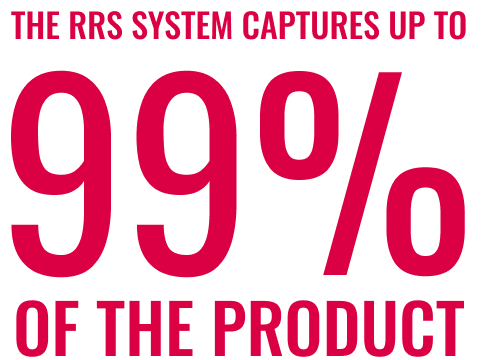

Mayor Rendimiento:

El sistema RRS captura hasta 99% del producto, lo que aumenta significativamente las tasas de rendimiento. A diferencia de los sistemas tradicionales de recolección de huesos, que suelen producir más desechos, el sistema RRS está diseñado para recuperar carne blanca más valiosa y reducir el desperdicio de carne roja.

Rentabilidad:

El sistema RRS tiene un costo que varía entre $18,000 y $28,000, dependiendo del tamaño, lo que lo convierte en una alternativa más asequible en comparación con otros sistemas.

Mejora en la Sanidad y el Mantenimiento:

Con menos piezas móviles, como motores y cajas de cambios, el sistema RRS reduce el riesgo de contaminación. Su diseño permite una limpieza más sencilla, lo que soluciona los problemas de higiene que existían anteriormente.

Configuración Simplificada:

El sistema RRS es más rápido y fácil de configurar, lo que reduce el tiempo de inactividad operativo y aumenta el rendimiento de producción.

Control de Temperatura para la Calidad del Producto:

Mantener temperaturas consistentes entre las placas primarias y secundarias es crucial para la calidad y vida útil del producto. El sistema RRS asegura un mejor control de temperatura, mejorando así la consistencia del producto.

Resultados e Impacto

Después de realizar pruebas exitosas del sistema RRS en 2018, el cliente comenzó a realizar la transición de sus plantas de producción al nuevo sistema, comenzando con su Planta Norte y luego instalando dos trituradoras adicionales en su Planta Forest Park. Como resultado, la empresa experimentó una mayor eficiencia, comentarios positivos del personal, un rápido retorno de su inversión y mejoras en el saneamiento.

El sistema RRS produjo una mejora sustancial en la eficiencia. La capacidad del sistema para recuperar casi todo el producto condujo a una reducción significativa de los desechos. El sistema también permitió a los operadores trabajar más rápido, lo que redujo el tiempo de preparación y mantenimiento.

Los supervisores y operadores de producción apreciaron la facilidad de uso y la calidad del producto final. El equipo informó que el diseño intuitivo del sistema y la configuración más sencilla dieron como resultado menos tiempo de inactividad y un proceso de producción más eficiente.

La capacidad del RRS para capturar productos más valiosos ayudó al cliente a obtener un rápido retorno de la inversión. En las instalaciones que procesan grandes volúmenes de carne picada, el retorno de la inversión suele verse en tan solo unas semanas desde la implementación.

El diseño simplificado del sistema RRS facilitó su limpieza y mantenimiento. El equipo de producción de la empresa informó que el nuevo sistema redujo significativamente el tiempo y el esfuerzo necesarios para la desinfección, lo que se tradujo en menos tiempo de inactividad de la producción y menores riesgos de contaminación.

Expansión Futura y Colaboración Continua

Gracias al éxito de la prueba e instalación de RRS, este cliente amplió el uso de los equipos de Rome en más instalaciones de producción. La mejora en el rendimiento, la reducción de los desechos y la mayor eficiencia operativa han posicionado a la empresa para el crecimiento futuro. Rome Grinding Solutions sigue trabajando en estrecha colaboración con clientes similares, ofreciendo asistencia constante y explorando formas adicionales de optimizar sus líneas de producción.

Conclusión

Esta colaboración demuestra el impacto transformador que pueden tener los equipos innovadores en las operaciones de procesamiento de carne. El sistema RRS de Rome no solo mejoró los índices de rendimiento, sino que también mejoró la eficiencia operativa, la higiene y la calidad del producto, lo que lo convierte en una solución ideal para los productores que buscan optimizar su producción de carne molida.

CONOZCA A LOS Brutus

El molinillo The Brutus presenta un tamaño ultra pequeño y ruedas opcionales para movilidad en moliendas de muestras más pequeñas, y está construido con acero inoxidable de alta calidad para una longevidad, durabilidad y flexibilidad excepcionales en cualquier entorno de producción de alimentos frescos.

CONOZCA A LOS TITAN

El molino Titan de Rome ofrece versatilidad y durabilidad, lo que permite cambios rápidos de producto para reducir el tiempo de inactividad y aumentar el rendimiento de la producción. Su diseño con piezas mínimas permite un desmontaje y montaje rápidos, lo que garantiza una desinfección fácil y eficiente.

Conoce a THE MAXIMUS

Diseñado para mejorar los procesos de producción de alimentos y aumentar el rendimiento, el molinillo Maximus ofrece resistencia, durabilidad y un rendimiento duradero para productos en bloques templados y congelados, así como para las necesidades de procesamiento de huesos y grasas.

Habla con un experto en Rome

1427 Western Avenue

Sheldon, Iowa 51201

Apartado Postal 186

800-443-0557