INTRODUCCIÓN

En agosto de 2020, un cliente de Rome Grinding Solutions se enfrentó a un desafío crítico en varias de sus plantas de producción de carne de vacuno. Las regulaciones del USDA exigían a la empresa que realizara inspecciones cada hora de los conjuntos de corte de sus picadoras de carne, una tarea que ralentizaba significativamente la producción. Para agravar el problema, el proceso de desmontaje y montaje del equipo requería el uso de una engorrosa llave inglesa de entre veinte y treinta libras, lo que suponía un riesgo para la seguridad de los trabajadores. La empresa necesitaba una solución que agilizara el proceso de inspección y aumentara la seguridad de los trabajadores.

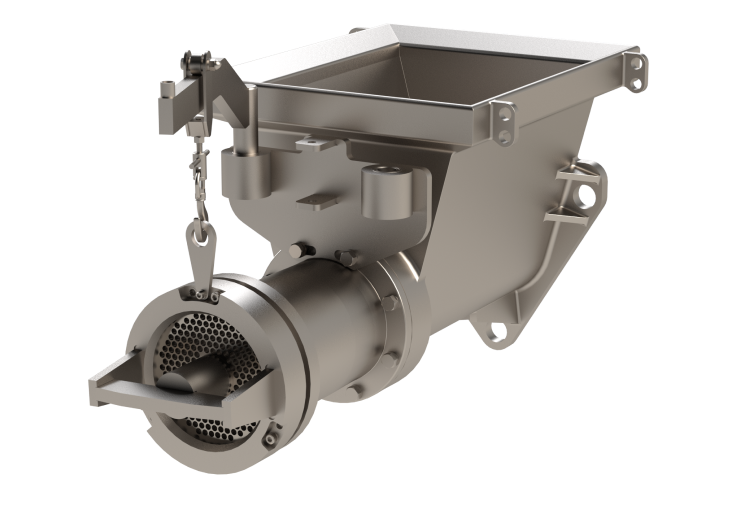

Para abordar estos desafíos, se recurrió a Rome Grinding Solutions, líder en la industria de la molienda de carne. El resultado fue el desarrollo del sistema de anillo de retención atornillable (BORR), una innovación que no solo mejoró la seguridad, sino que también permitió al cliente minimizar el tiempo de inactividad y aumentar la eficiencia de la producción.

El Desafío

Las plantas de producción de carne de vacuno producen enormes cantidades de carne diariamente. En cumplimiento con los requisitos del USDA, este cliente tenía que inspeccionar los conjuntos de corte de sus picadoras una vez cada hora. Cada inspección llevaba aproximadamente diez minutos por picadora, una interrupción aparentemente pequeña que se acumulaba rápidamente, en particular teniendo en cuenta el gran volumen de carne que se producía. En el transcurso de una jornada laboral, este tiempo de inactividad representaba un importante cuello de botella en la producción.

Además, las preocupaciones en materia de seguridad eran reales. El método tradicional para apretar y aflojar el anillo de retención implicaba una llave inglesa pesada, que resultaba difícil y peligrosa de manejar para los trabajadores. Los equipos de innovación y automatización del cliente buscaban una solución que no solo redujera el tiempo de inactividad, sino que también eliminara la necesidad de herramientas tan peligrosas, mejorando así la seguridad en el lugar de trabajo.

“El sistema V2 BORR fue diseñado para utilizar piezas fundidas de materiales estándar, lo que redujo los costos y garantizó que el sistema se mantuviera dentro del presupuesto”.

La Solución: El Sistema BORR de Rome

En respuesta a estas necesidades, Rome Grinding Solutions diseñó y desarrolló el sistema de anillo de retención atornillable (BORR). Esta solución innovadora permitió desmontar y volver a montar rápidamente los equipos de molienda sin necesidad de herramientas pesadas, lo que permitió abordar tanto las ineficiencias de producción como los riesgos de seguridad.

El desarrollo del sistema BORR siguió un cronograma estructurado:

Ryan Van Maasdam, de Rome Grinding Solutions, se reunió con el cliente para analizar los desafíos y las posibles soluciones. Rome comenzó de inmediato a diseñar el sistema BORR.

Menos de una semana después, Rome presentó el dibujo conceptual inicial del sistema BORR, aunque uno de los primeros desafíos fue encontrar una llave de torque capaz de aplicar tensión uniforme en todos los pernos.

Una reunión casual en una gasolinera proporcionó la solución. Van Maasdam fue presentado a Air Automation Engineering, una empresa que fabrica llaves de torque programables, la herramienta exacta que se necesitaba para que el sistema BORR funcionara según lo previsto.

En menos de un mes, Rome completó el montaje del BORR V1. Los representantes del cliente visitaron las instalaciones de Rome para inspeccionar y aprobar el sistema.

Más tarde ese otoño, el sistema V1 se instaló en una de las plantas de producción del cliente, lo que marcó la primera implementación exitosa.

Basándose en los comentarios de la instalación inicial, Rome realizó varias modificaciones de diseño para mejorar el sistema durante los meses siguientes. El sistema BORR V2 se diseñó para utilizar piezas fundidas de materiales estándar, lo que redujo los costos y garantizó que el sistema se mantuviera dentro del presupuesto. En enero, el sistema V2 estaba completamente instalado y optimizado para su uso en producción.

Resultados e Impacto

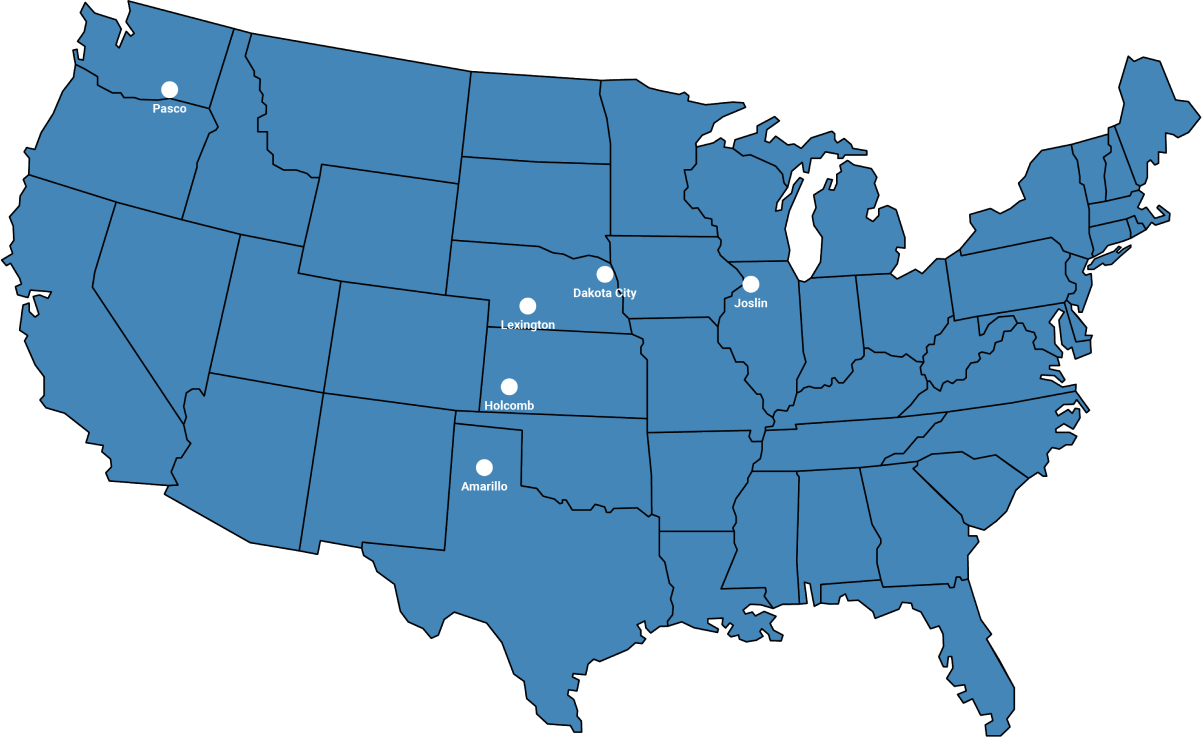

Desde la instalación del sistema BORR, el productor industrial de carne vacuna lo ha implementado en seis de sus instalaciones de producción de carne molida más grandes, incluidas las ubicaciones en:

- Amarillo, TX

- Lexington, NE

- Dakota City, NE

- Holcomb, KS

- Joslin, IL

- Pasco, WA

El sistema BORR generó mejoras significativas en todas las operaciones:

Mayor eficiencia de producción: Al reducir drásticamente el tiempo necesario para las inspecciones por hora, el sistema BORR minimizó el tiempo de inactividad. Este cliente vio ganancias inmediatas en el rendimiento de la producción, ya que producía más carne en menos tiempo. Dada la escala de sus operaciones, estos ahorros de tiempo se tradujeron en aumentos sustanciales en la producción diaria.

Mayor seguridad para los trabajadores: El sistema BORR eliminó la necesidad de que los trabajadores usaran llaves inglesas pesadas, reduciendo significativamente el riesgo de lesiones y creando un entorno de trabajo más seguro y ergonómico.

Ahorro de costes: Gracias a las revisiones de diseño que dieron lugar al sistema V2, Rome pudo estandarizar el uso de materiales y mantener los costos de producción bajo control. Esto permitió al cliente implementar la solución sin exceder las limitaciones presupuestarias, lo que mejoró aún más el valor del sistema.

“El cliente observó ganancias inmediatas en el rendimiento de la producción, ya que pudo producir más carne en menos tiempo”.

Viendo Hacia el Futuro

Esta asociación ha demostrado el poder de la innovación para resolver los desafíos reales de la producción de alimentos. El éxito del sistema BORR no solo resolvió las preocupaciones inmediatas de nuestro cliente en materia de seguridad y eficiencia, sino que también allanó el camino para una futura colaboración entre las dos empresas.

Seguimos explorando oportunidades para integrar más automatización y tecnología innovadora en los procesos de producción futuros. A medida que evoluciona la industria de producción de alimentos, el sistema BORR de Roma es un excelente ejemplo de cómo las soluciones con visión de futuro pueden impulsar mejoras tanto en la productividad como en la seguridad.

Conclusión

El sistema de anillos de retención atornillables (BORR) de Rome Grinding Solutions ha demostrado ser un cambio radical. Al abordar los desafíos duales de las ineficiencias de producción y la seguridad de los trabajadores, Rome ayudó a aumentar el rendimiento de la producción y, al mismo tiempo, garantizar un entorno más seguro para los trabajadores.

A medida que las empresas de producción de alimentos continúan ampliando sus operaciones, innovaciones como el sistema BORR serán clave para mantener la ventaja competitiva, mejorar la seguridad en el lugar de trabajo y optimizar los procesos de producción en todas las instalaciones.

CONOZCA A LOS Brutus

El molinillo The Brutus presenta un tamaño ultra pequeño y ruedas opcionales para movilidad en moliendas de muestras más pequeñas, y está construido con acero inoxidable de alta calidad para una longevidad, durabilidad y flexibilidad excepcionales en cualquier entorno de producción de alimentos frescos.

CONOZCA A LOS TITAN

El molino Titan de Rome ofrece versatilidad y durabilidad, lo que permite cambios rápidos de producto para reducir el tiempo de inactividad y aumentar el rendimiento de la producción. Su diseño con piezas mínimas permite un desmontaje y montaje rápidos, lo que garantiza una desinfección fácil y eficiente.

Conoce a THE MAXIMUS

Diseñado para mejorar los procesos de producción de alimentos y aumentar el rendimiento, el molinillo Maximus ofrece resistencia, durabilidad y un rendimiento duradero para productos en bloques templados y congelados, así como para las necesidades de procesamiento de huesos y grasas.

Habla con un experto en Rome

1427 Western Avenue

Sheldon, Iowa 51201

Apartado Postal 186

800-443-0557