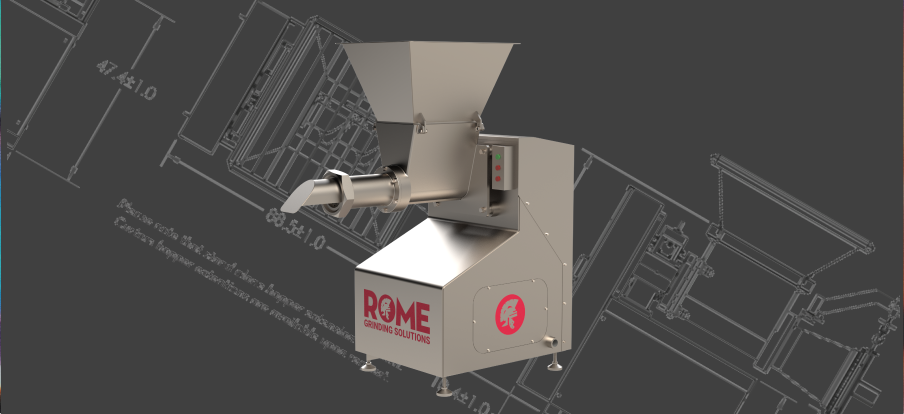

Meet the Brutus

Industrial food manufacturers play a crucial role in putting food on the table for families around the world. From juicy burgers to wholesome vegetable products, every bite of food relies on equipment that ensures safety, efficiency, and consistent quality. That’s why we developed the Brutus — a powerful, versatile solution designed to help manufacturers make food for families as safely and efficiently as possible.

See how the Brutus supports industrial food manufacturers in producing high-quality, safe food, all while improving operational efficiency.

Safety-First Design for Peace of Mind

Facing stringent regulations and a growing focus on consumer health, food producers need equipment they can rely on to maintain the highest safety standards. The Brutus is built with safety as a top priority.

Integrated Safety Shield

The Brutus 6-inch grinder comes equipped with an integrated safety shield and the Brutus 8-inch grinder has an outside mounted shield, protecting operators from potential hazards during production. This design reduces the risk of accidents and ensures compliance with workplace safety standards, giving food manufacturers peace of mind that their team is protected.

Sanitary Design

Since contamination risks can affect both product quality and safety, hygiene is crucial in food production. The Brutus features a hygienic-focused design that simplifies cleaning and reduces bacterial buildup. With smooth surfaces, easy disassembly, and stainless steel construction, these grinders help food producers meet stringent USDA and FDA sanitation requirements.

All-Stainless Steel Construction

Unlike competitors’ models, which may be prone to rust or corrosion, the Brutus is built from durable stainless steel, which not only ensures longevity but also supports a clean, contaminant-free environment. Whether you’re producing meat, vegetables, or dairy, this high-grade material keeps the process sanitary from start to finish.

Efficiency That Scales to Meet Family-Sized Demands

The Brutus grinder has been engineered to meet the vast needs of small to mid-sized producers, offering high output as global food demand continues to rise, while maintaining a compact footprint.

Small Footprint, Big Impact

While the Brutus grinders don’t take up much floor space, they deliver high-volume performance that’s perfect for a variety of food production applications. The Brutus 6-inch grinder has a holding capacity of up to 140 pounds, with an optional 400-pounds or greater hopper extension, and can process everything from beef and poultry to vegetables and cheese. The Brutus 8-inch grinder goes even further, with the capability to grind up to 40,000 pounds per hour during the initial grind.

Versatility for Every Application

The Brutus isn’t limited to a specific food type. Whether manufacturers are producing fresh meat, by-products, seafood, or fruits and vegetables, the Brutus can handle it all. The flexibility of both models allows food producers to switch between coarse and fine grinds with ease, enabling quick changeovers between product types. From USDA sample runs to full-scale production, the Brutus can accommodate diverse production needs.

Rome Reclaim System (RRS)

To further optimize efficiency, Rome offers the Rome Reclaim System (RSS), which integrates seamlessly with the Brutus 8-inch grinder. This bone collection and reclaim solution can be installed in just ten minutes, helping producers reduce waste and maximize profitability. With no extra power sources needed and an intuitive setup, it’s a cost-effective way to manage production waste while maintaining a sanitary workspace. The Brutus 6-inch grinder can have a traditional bone collection system installed.

Durability Built to Last in the Toughest Environments

Operating in some of the most demanding environments, food producers require reliable, long-lasting equipment. The Brutus grinder is engineered for durability and longevity, ensuring they can handle tough applications without frequent breakdowns or excessive wear.

Heavy-Duty Performance

The Brutus grinder is more durable than other grinders in their category. Built from stainless steel or carbon steel, depending on the producer’s preference, these grinders are designed to withstand the most abrasive conditions, from rendering plants to small and mid-sized processing facilities.

Designed for Harsh Applications

Unlike competitors’ equipment, which might falter under intense use, the Brutus grinder is specifically built to handle harsher applications, such as high-fat content and tough materials like seafood or offal. Their robust construction ensures they stay operational longer, reducing downtime and minimizing the need for costly repairs or replacements.

Made in the USA

All Brutus grinders are manufactured in the U.S., using high-quality parts that are readily available for maintenance or upgrades. This ensures that food producers have the support they need, with quick access to replacement parts and service options to keep operations running smoothly.

Helping Food Manufacturers Meet High Standards

Industrial food manufacturers are under constant pressure to produce food that is not only delicious but also safe, consistent, and affordable. Rome Grinding Solutions’ Brutus grinder helps meet these challenges by offering a solution that combines safety, efficiency, versatility, and durability. With the Brutus grinder, food manufacturers can confidently produce food that families around the world can trust.

Whether you’re grinding meat for burgers or reducing vegetable products for ready-made meals, the Brutus delivers the performance you need to keep your production line moving and your customers satisfied.

Want to see how the Brutus can help your operation produce safe, high-quality food efficiently? Contact us today to learn more or to request a demo of the Brutus 6-inch or Brutus 8-inch grinder.

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557