Why Grinder Audits Are Essential for Your Operation

Downtime is costly for food production companies and equipment efficiency is critical. Yet, when we reach out to schedule grinder audits, we often hear, *“We’re too busy right now—let’s wait until after the busy season.”* While this might seem logical, our Grinder Specialists know it’s a risky gamble. After all, would you wait until after the race to tune up your car?

Audits aren’t just about maintenance—they’re about preventing small issues from becoming costly disruptions. Here’s why investing time in a grinder audit now can save your operation time, money, and stress in the long run.

What Is a Grinder Audit?

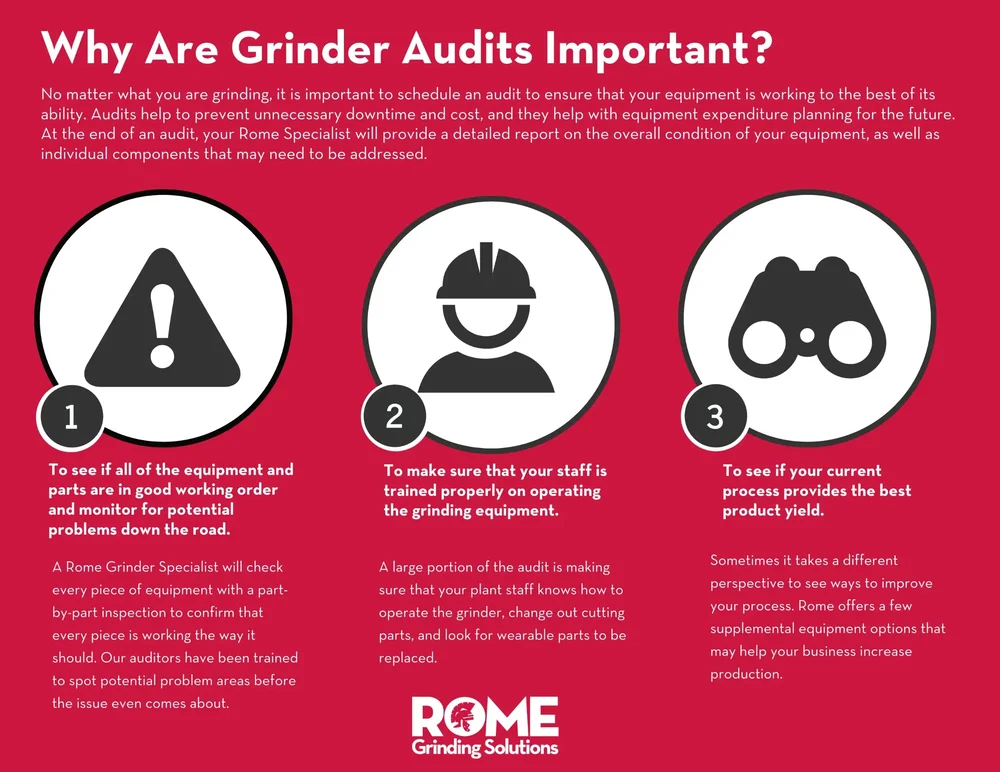

A grinder audit is a comprehensive inspection conducted by Rome’s Grinder Specialists to assess the condition of your equipment, identify potential issues, and provide actionable recommendations for improvement. It’s a proactive approach to ensure your grinder is operating at peak performance while minimizing risks of unexpected downtime.

Top 3 Reasons Grinder Audits Are Critical

#1. Catch Small Problems Before They Escalate

During audits, our specialists often uncover minor issues—worn pins, bent knife holder arms, or aging bushings—that can escalate into major failures if ignored. A single damaged component could lead to an unplanned shutdown in the middle of peak production, costing you valuable time and revenue. By addressing these concerns early, you not only prevent breakdowns but also improve your grinder’s longevity and efficiency.

#2. Ensure Staff is Properly Trained

Even the best equipment won’t perform optimally if it’s not operated correctly. A grinder audit includes staff training to ensure your team knows how to operate the grinder efficiently, identify wearable parts that need replacement, and swap out cutting parts safely and effectively. Proper training reduces operator errors, enhances safety, and ensures your grinder operates at its full potential.

#3. Optimize Your Process for Better Yield

Sometimes, a fresh perspective reveals opportunities for improvement. Our specialists can recommend process tweaks or supplemental equipment that may boost your production yield. Whether it’s a minor adjustment or a new solution, these insights can lead to measurable gains in output and efficiency.

Timing Matters

Delaying an audit might seem like a practical choice during busy seasons, but it can be risky. Peak production is when your grinder is under the most strain—making it the ideal time to ensure everything is in top condition. With Rome’s flexible scheduling, audits can be conducted with minimal disruption to your operations.

What You’ll Gain from a Rome Grinder Audit

At the end of your audit, you’ll receive a detailed report covering the overall condition of your grinder and its components, recommended spare parts to keep on hand, and process improvement suggestions to enhance production and yield. This valuable insight helps you prevent unexpected downtime, plan for future equipment investments, and optimize your operation.

Proactive Maintenance Pays Off

A grinder audit isn’t just an inspection—it’s an investment in your operation’s success. Whether it’s extending the life of your equipment, preventing costly breakdowns, or improving your team’s expertise, the benefits far outweigh the time commitment.

Don’t wait for a problem to arise. Schedule your grinder audit today and let Rome Grinding Solutions help you stay ahead of the curve. Contact us now to learn more!

1427 Western Avenue

Sheldon, IA 51201

PO Box 186

800-443-0557